How does it work ?

MAX FRESH Technology

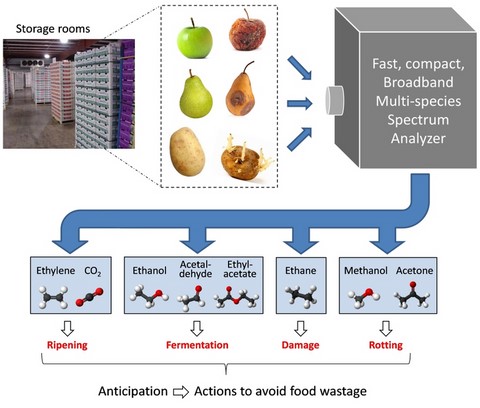

The technology of MAX FRESH to detect gasses / volatiles, is based on MID-INFRARED adsorption. By measuring emitted volatiles and monitoring the trend of these volatiles (VOC's) during storage , we are able to get a fingerprint of the quality of the stored fruits and vegetables. Based on daily measurements , the decision-making-model of Max Fresh gives relevant information about :

- the stage of ripening / sensecense of the fruit

- the decomposition / rot development during storage

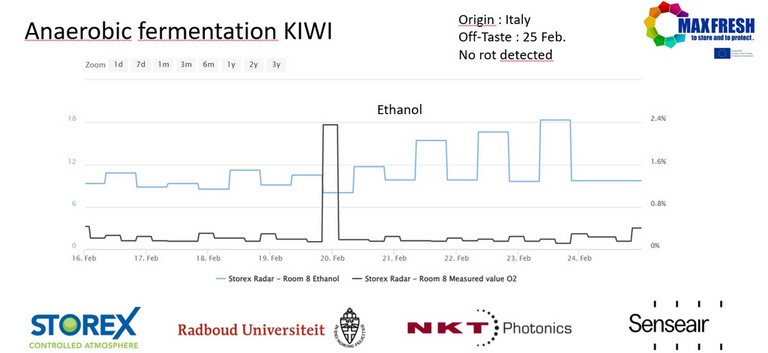

- the point of anaerobic fermentation (ACP)

Safeguarding fruit quality - ripening

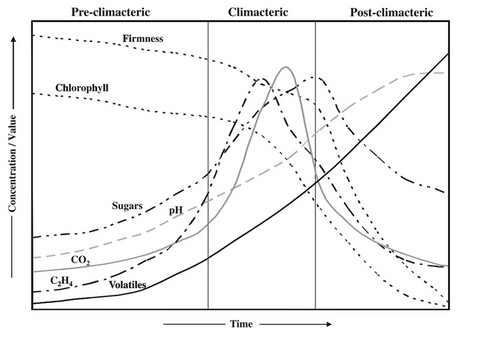

The MAX FRESH system is able to detect relevant volatiles which are produced by the process of ripening such as ethylene. By measuring each storage room on a daily basis, the system provides an accurate overview / trend of the maturation / senescence of the fruit. The decision-making-model based on the Max Fresh measurements, provides the storage operator an excellent tool to (re)act in time to prevent significant loss of quality .

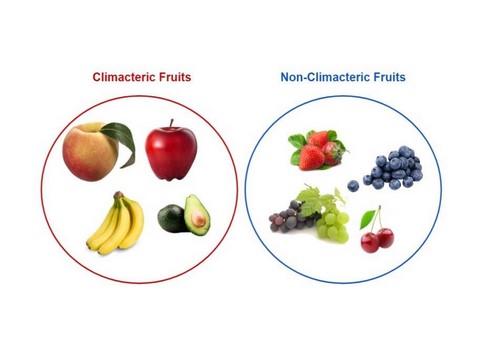

Generally, fleshy fruits can be divided into two groups based on the presence or absence of a respiratory increase at the onset of ripening. This respiratory increase -- which is proceeded, or accompanied, by a rise in ethylene -- is called a climacteric, and there are marked differences in the development of climacteric and non-climacteric fruits. Climacteric fruit can be either monocots or dicots and the ripening of these fruits can still be achieved even if the fruit has been harvested at the end of their growth period. Non-climacteric fruits ripen without ethylene and respiration bursts, the ripening process is slower, and for the most part they will not be able to ripen if the fruit is not attached to the parent plant.

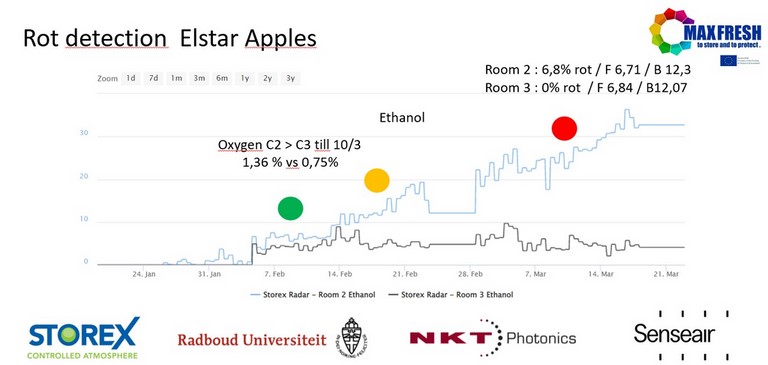

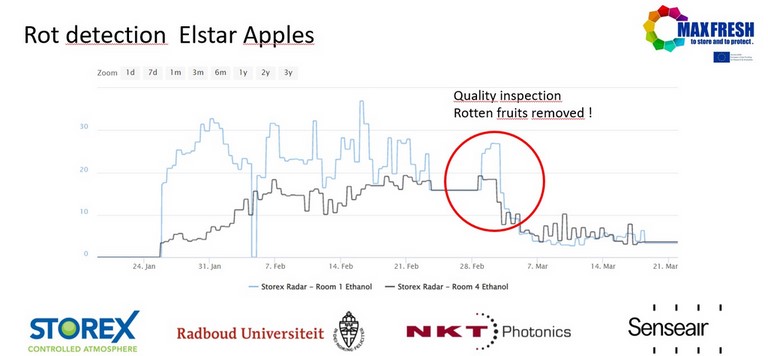

Decomposition / Rot detection

Safe and secure DCA Storage

Anaerobic fermentation experiment Max Fresh with kiwi's.

Testimonial

In a world of seven billion people, set to grow to nine billion by 2050, wasting food makes no sense – economically, environmentally and ethically, aside from the cost implications, all the land, water, fertilisers and labour needed to grow that food is wasted – not to mention the generation of greenhouse gas emissions produced by food decomposing on landfill and the transport of food that is ultimately thrown away.”

Achim Steiner, UN Under-Secretary - General and UNEP Executive Director